Then caulk all joints with a high grade 50 year paintable silicone or polyurethane product to prevent water from getting behind the siding.

How to use flashing to protect wood siding.

It is always recommended to install step flashing behind stucco dryvit wood panel lap siding vinyl siding cedar shingle siding etc.

Nail it to the sidewall or glue it if nailing isn t possible.

If the kick out and step flashing can t tuck behind the siding screw on cap flashing to cover it then caulk along the top.

Here are four ways to use metal flashing to prolong the life of siding.

Prime all bare spots with a high grade oil based primer.

In areas where snow may build up add a wide band of peel and stick membrane over the step flashing but under the sheathing wrap as shown.

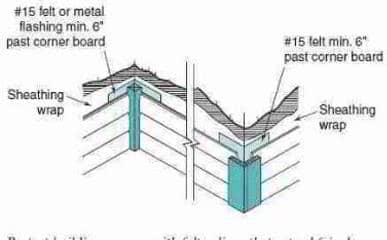

Building siding flashing finish details for building corners.

Flush the end of the flashing length with the wall corner and secure the flashing to the framing with an 8d nail at each wall stud.

Tinting a standard white primer a shade or two lighter than the finish coat improves coverage.

Lift the bottom shingle and slip in the kickout flashing.

Cover with cap flashing.

Use overlapping 1x4s or 1x6s at outside corners or use 5 4 stock for a heavier look.

Where the step flashing terminates along a sidewall is a common trouble spot for moisture problems.

Otherwise dripping water will leave its mark along the siding.

Slip in the flashing.

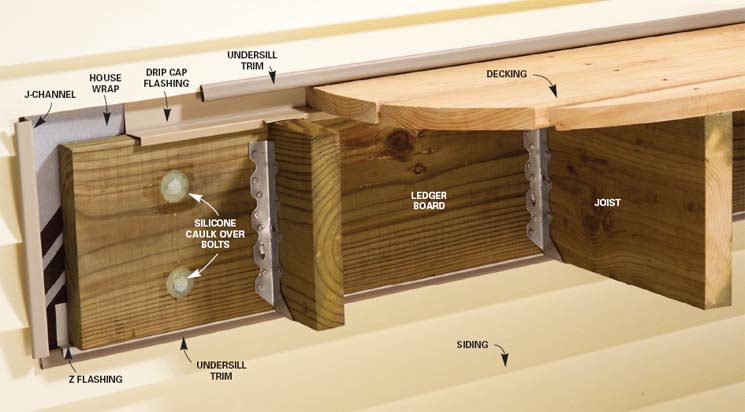

Begin at either end of the wall and set the level middle section of the z flashing onto the top edge of the siding panel with the wider flange upward and against the wall framing.

Many times builders fail to use proper flashing at the top of windows.

Caulk any joint that allows this to happen.

Use a felt paper spline wrapped around the corner and extending 6 inches beyond the corner board to protect the joints where the siding meets the corner boards see figure 1 5 at left.

When it comes to flashing siding corners many builders simply use a 1x wood corner.

The best solution is a preformed or custom bent kick out flashing to divert the water away from the siding.

There are many different metal flashing shapes but in your case the metal laps over the fascia board perhaps 1 4 inch then is bent at a 90 degree angle to pass over the top of the fascia board then bent again at a 90 degree angle to go up the wall so that it extends behind the first row of vinyl siding.