Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity.

Identify the three basic types of sheet metal working operations.

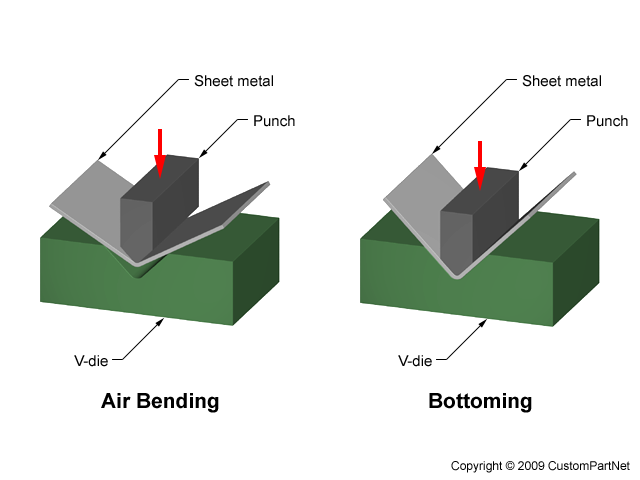

A punch and die is applied for this type of sheet metal operation.

The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing.

22 different types of lathe machine operations.

What makes shearing different from the other two operations.

Most part defects such as splits and wrinkles occur in forming operations.

3 what is the difference between deep drawing and bar drawing.

In this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles.

All forming operations deform sheet material by exposing it to tension compression or both.

Previous question next question.

1 identify the three basic types of sheet metalworking operations 2 the three basic sheet metalworking operations are bending drawing and shearing.

100 4 ratings a the three basic types of sheet metalworking operations are drawing cutting and bending.

4 what is springback in sheet metal bending.

The metal being formed must have the ability to stretch and compress within given limits.

Identify the three basic types of sheet metalworking operations.

Successful sheet metal forming relies heavily on the metal s mechanical properties.

Drawing is a sheet metalworking operation used to produce cup shaped or box shaped or other complex curved hollow parts.

B a the tooling used in sheet metalworking operations are punch and die.

View the full answer.

In which enough scrap is left all around as shown in fig.

The three basic types of sheet metalworking operations are 1 cutting 2 bending and 3 drawing.

In blanking of a round sheet metal part indicate how the clearance should be applied to the punch and die diameters.